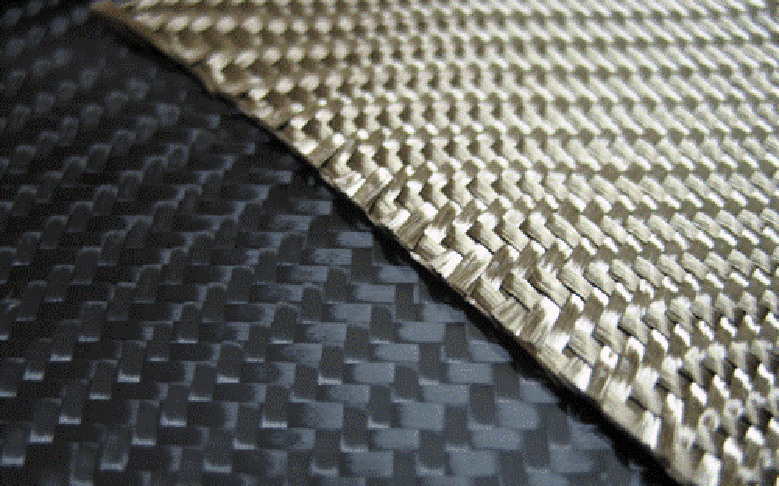

Continuous Basalt Fiber (CBF) can be used to make a variety of durable and heat-resistant products including fabrics that mimic carbon fiber and S-glass.

PISCES successfully secured a contract last month with SMA—a defense and aerospace consulting firm based in Irvine, California—to conduct a market study on the feasibility of a Continuous Basalt Fiber (CBF) manufacturing operation in Hawaii County.

Research shows Hawaii’s basalt has the specific chemical profile needed to manufacture CBF, a lesser-known product with myriad uses that mimic fiberglass and carbon-fiber. CBF products offer resistance to corrosion and heat, and high tensile strength. Globally, CBF manufacturing is valued at around $100 million and expected to double in the coming decade, according to estimates.

The study, which started March 20, 2018, will prepare a comprehensive report discussing the current market demand for CBF, manufacturing capabilities world-wide and the market price. The study will also determine the cost to build and operate a CBF plant on Hawaii Island and provide a business model to determine whether it would benefit the local economy. Further, the analysis will provide estimates for the cost of basalt fiber manufactured in Hawaii County verses other locations, as well as the potential for new jobs and wages.

PISCES has been working with Hawaiian basalt as a feedstock for ISRU (in-situ resource utilization) technology since 2014. The research is intended to develop usable resources for space exploration and Earth-based applications using locally sourced, raw materials.

The study was funded by the State of Hawaii. It will be completed by July 10, 2018.

To request a copy of the completed study, please contact us at dbedt.pisces@hawaii.gov.